Dynamic Under Keel Clearance

DUKC® is an Aid to Navigation that manages a ship’s under-keel clearance (UKC).

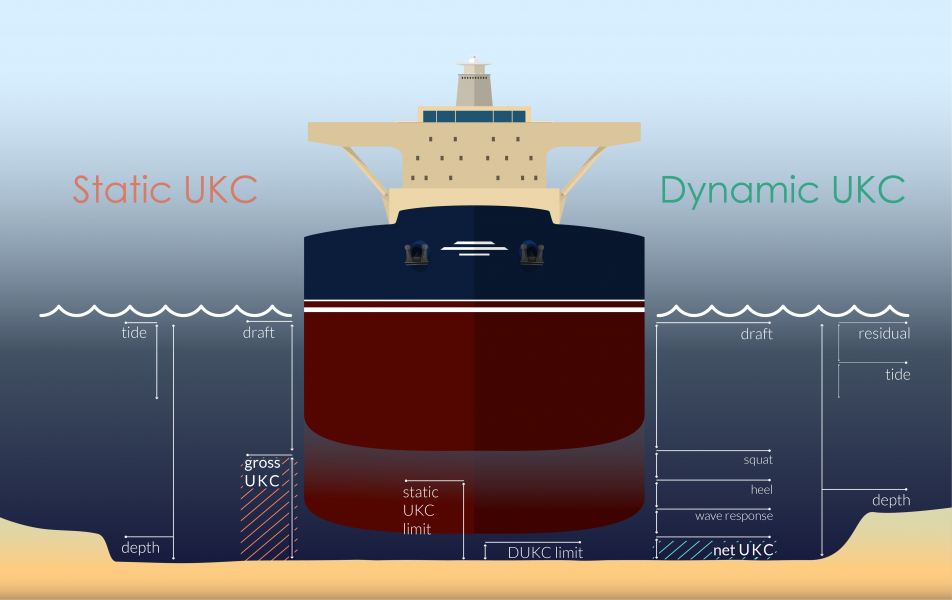

UKC is the depth of water available underneath the vessel whilst it is underway, after allowing for the motions of the ship.

DUKC® ensures every vessel has sufficient UKC for a safe transit, considering the environmental conditions during the voyage.

DUKC® Integrates:

Bathymetry

data

Ship speed

Heading

Real-time tide & wave measurements

to calculate:

Ship Motions

The ship motions will change based on a number of factors including:

Height & period

of the waves

Length, beam, type,

& stability of the vessel

By dynamically modelling each UKC component and then adding an additional safety allowance; DUKC® transits achieve an accuracy and safety that far exceed traditional static rules that assume fixed allowances from which UKC components must be accounted for.

DUKC® models are specifically configured and validated based on full-scale measurements at the port, and comply with international standards for safety of navigation in shallow waterways.

Features

Transit Planning

Maximum sailing drafts and sailing window are determined based on prevailing environmental conditions and the actual vessel. Accurate UKC is determined using real-time and forecast environmental data, vessel characteristics, high resolution bathymetry, and transit specifics including speeds and headings.

Transit Monitoring

Vessels in transit are automatically monitored via AIS. UKC calculations are continuously updated based on the vessel’s actual speed and position, as well as for the latest environmental data. Pilots, Harbour Master and VTS Operators have real-time visibility of the UKC for every transit.

Chart Overlay

Dynamic Chart Overlays provide intuitive go and no-go areas overlaid on navigation charts. These are based on high resolution bathymetry and vessel motions including squat and wave response. They are predictive in that they advise what the UKC situation will be at every point along a channel at the time when the vessel is expected to reach that location.

Voyage Planning

Using astronomical tides, climate statistics, and probability distributions, Voyage Planning provides long range advice of expected sailing drafts months in advance.

Met-Ocean Data

Customisable displays of critical real-time measured and forecast environmental data including, winds, waves, tides, and currents. Displays can be tailored for different user groups or scenarios.

Reporting

All transit and calculation data is logged and archived, providing auditability and data mining capability.

DUKC® Clients

DUKC® Case Studies

Port Hedland

OMC undertook a comprehensive dredge optimisation study for a major capital dredging project. Utilising DUKC® technology reduced the dredged depth requirements by more than 1m, and the overall dredged area by 90,000m2.

Port of Geelong

OMC worked alongside the Victorian Regional Channels Authority (VRCA) to deliver an operational DUKC® system for the Port of Geelong. Vessel motion measurements were carried out on some of the biggest vessels that had ever visited Geelong.

Melbourne Suezmax Tanker Accessibility

The Port of Melbourne and one of their major port users, ExxonMobil, wanted to investigate the possibility of bringing vessels with a deeper draft than the 14.0 m design maximum draft of the channels.

More Case Studies

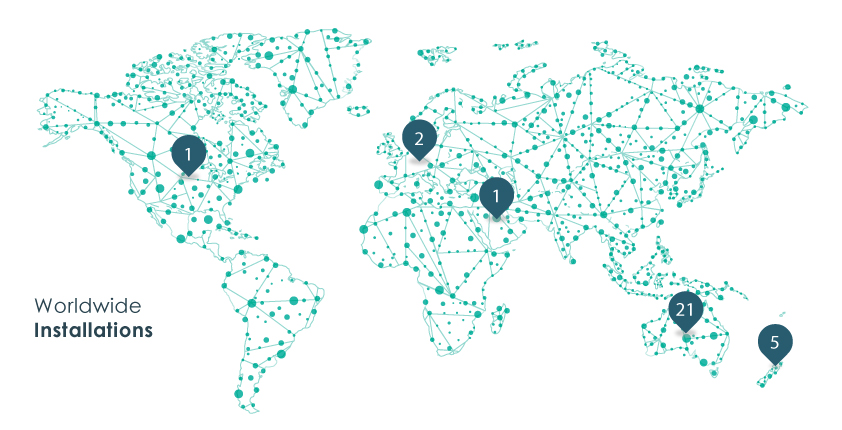

We have serviced many clients and like to share our success stories. The case studies are from all around the world. Find a port/waterway with a similar issue and see how we were able to solve their problem.

Contact us for more information

Please refer to our Privacy Policy and Collection Statement before entering your details.